The aluminum enclosure is one of the primary components in several industries, protecting electronic devices and ensuring their longevity. So, when it comes to choosing the right aluminum enclosure, there are two most popular choices emerge: one is extruded, and another is die-cast enclosures. Each type has its own features and benefits. This guide will discuss what type of aluminum enclosures can be perfect for you according to your budget and requirements.

An Overview of Die Cast Enclosures

Die-casting is mainly the manufacturing process that involves injecting molten metal, often aluminum, into a mold under excessive pressure. It results in an accurately shaped aluminum enclosures with a smooth finish.

This type of enclosure is known for its high durability, high structural integrity, and capability to get intricate designs. They are widely used in several applications, like automotive components, industrial equipment, and consumer electronics.

What Is Extruded Enclosures?

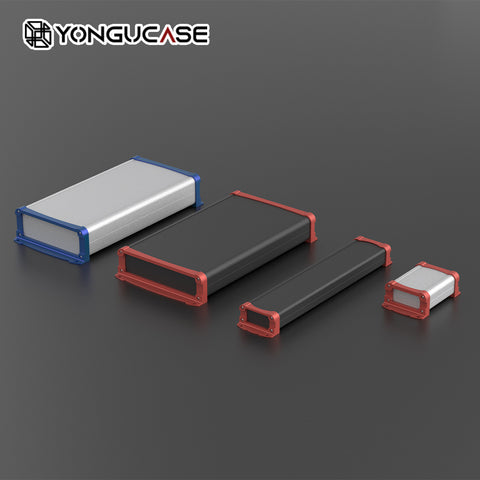

Extrusion is when the aluminum is forced through a shaped die to produce a continuous profile. An extruded aluminum enclosure is characterized by its unique straight shape with uniform cross-sections.

This specific manufacturing method allows for cost-efficient production of customized lengths, making it a perfect pick for several applications requiring specific dimensions. The extruded enclosure is valued because of its versatility, ease of customization, and thermal conductivity.

Primary Differences Between the Extruded and Die Cast Enclosures

Though both enclosures are used for several purposes in different industries, there are some key differences between these two aluminum enclosures. So, let's understand it in detail.

· Cost

One of the significant differences between extruded aluminum electronic enclosures and die cat enclosures is price. The extruded enclosures come at low prices compared to the die-cast ones because of the simplicity of the extrusion process. On the other hand, die-cast is expensive due to its specialized equipment.

· Design

Design flexibility is another key difference between these two enclosures. The die-cast enclosure excels in complex and intricate design, while the extruded enclosures are known for simple design. The molds used in the die-cast enclosures allow for precise dimensions. In contrast, the extruded enclosures are made for those applications where intricate design is not a priority.

· Usage

The usage of die-cast and extruded aluminum enclosure is different as well. The die-cast enclosures, with their durability, are often preferred in demanding environments where protection against vibration and harsh elements is needed. Extruded enclosures are better for less demanding applications where low cost with simple design is required.

Which One Is the Right for You: Extruded or Die Cast?

Choosing between the die-cast and extruded aluminum electronic enclosures depends on your specific requirements. If you prioritize structural integrity, intricate design, and durability at a higher price, die-cast is the ideal option for you.

But, if you prefer simplicity, versatility, and cost-effectiveness, choose the extruded enclosure. However, be careful when choosing any of them and assess each consideration to make an informed decision.

Conclusion

In the world of aluminum enclosures, the choice between the extruded and die-cast variants is a crucial decision. So, research properly and analyze all the elements before you make a decision. After a comprehensive understanding, select one that aligns seamlessly with your project requirements.