Aluminum enclosures are always considered a smart choice for transporting, protecting, and storing sensitive equipment. It is also ideal for applications exposed to corrosive environments, extreme temperatures, and even high electromagnetic fields.

However, if your question is why aluminum enclosures have become so popular, in this guide, we will let you know some exceptional benefits of a custom aluminum enclosure that will help you to decide why this is considered an excellent option for your home or office purposes.

Why Use a Custom Aluminum Enclosure?

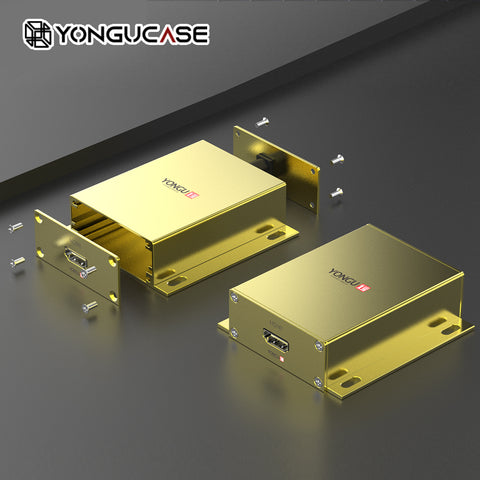

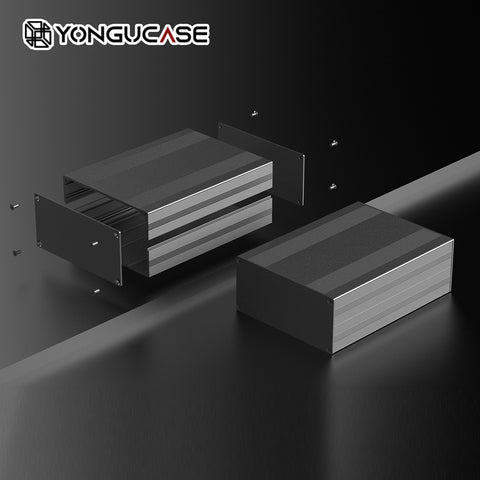

Custom enclosures show a vast range of usage in different industries. These are used to protect some house electronic components. Leading manufacturers often develop custom electronics cases for consumer electronics, automotive electronics, medical devices, industrial control systems, and many more. These custom-machined enclosures can protect different devices from electromagnetic, environmental, and even some high radio frequency interference.

In addition to ensuring safety, the custom enclosures are ideal for protecting many electronic components and devices. They also prevent contaminants such as dirt, chemicals, and moisture and protect from physical hazards. Therefore, this is highly preferred for mitigating the chances of electric shock.

Take a Look at The Benefits of Using the Custom Aluminum Enclosure

An aluminum project box can be used for different purposes. However, is it crucial to keep a few points in mind? So, check the key points and learn why you can choose the best aluminum enclosure.

- Extremely Strong

The aluminum strength offers much better toughness compared to other materials. The enclosure is resistant to the mechanical breakage. It does not deal with the aluminum enclosure's stress, tear, or cracks.

- Extraordinary Resistance to Corrosion

Aluminum is highly resistant to different substances. It could even cause corrosion and even the weathering. Sometimes, the exposure to the UV rays for long periods does not affect the enclosure.

- Insensitive to Temperature Extremes

Aluminum has characteristics that remain positive over a wide temperature range. It could vary from 80 °C to + 150 °C. Even in cold weather, the aluminum enclosures do not get fragile and brittle easily. Meanwhile, the tensile strength of this enclosure can deal with elasticity. The low coefficient of the thermal expansion allows it to sustain the higher temperatures without the distortion issue.

- Low-Cost Customization

Aluminum enclosures can be easily customized for different purposes like laser cutting, drilling, welding, riveting, brazing, and soldering. There's no need to pay any additional amount for the special mold. Aluminum is often used more easily than other materials for modifying different things.

Conclusion

A custom aluminum alloy enclosure is the best option to use. It can even safeguard and protect high-end equipment in different applications. Many product designers and leading manufacturers can utilize these enclosures as the best and most effective solution for preserving necessary equipment from moisture, rust, and electric shock in electronic devices.